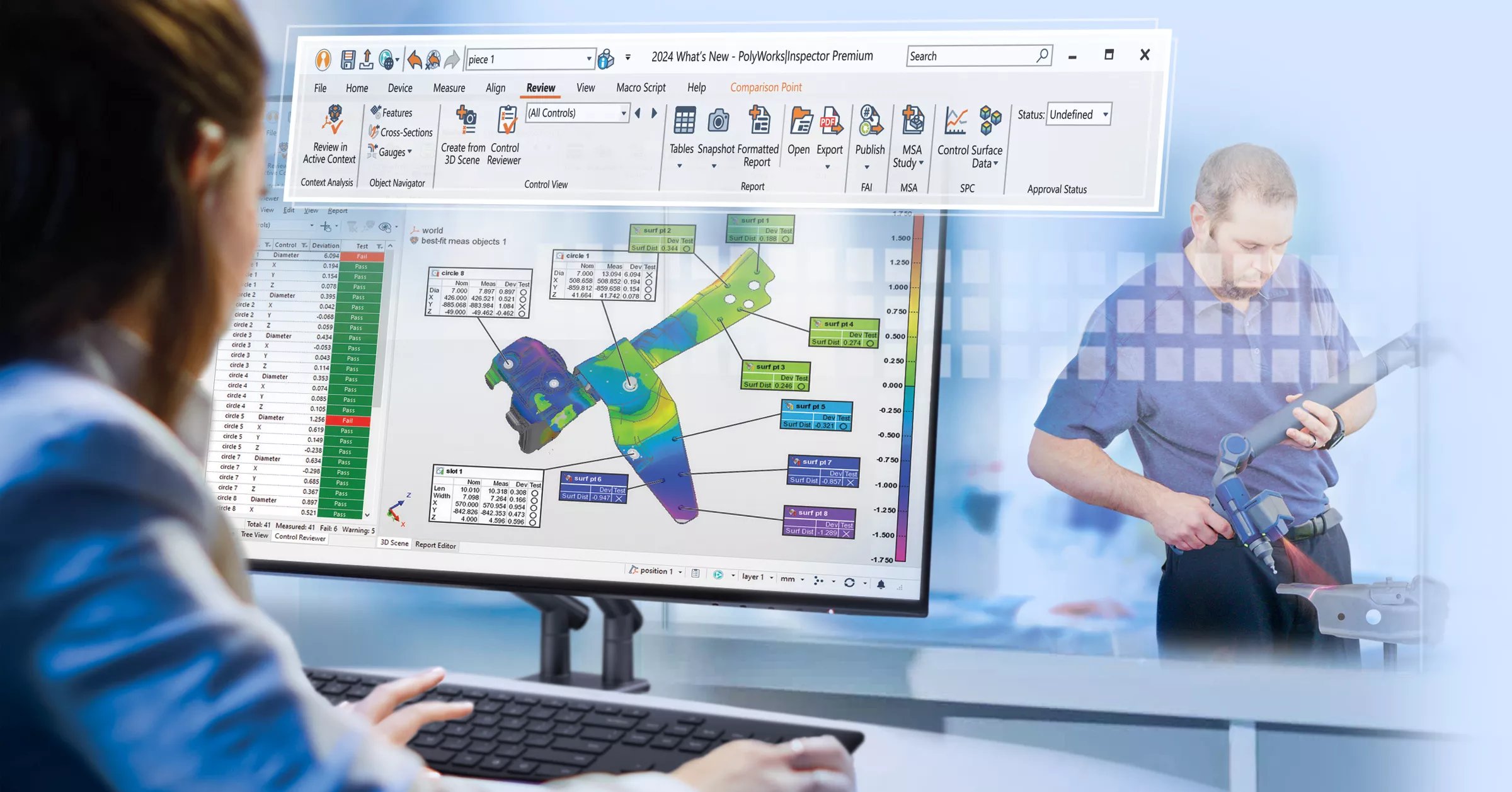

What’s New in PolyWorks|Inspector™ 2024

3D Dimensional Analysis & Quality Control

Improve 3D Measurement Efficiency with our Re-Engineered User Interfaces

Our significant investments in improving software usability year after year directly reflect our core value of ensuring customer success. PolyWorks|Inspector 2024 delivers major gains in efficiency through its re-engineered user interfaces:

- Perform inspection tasks and discover new tools intuitively as we have merged all toolbars and the main menu bar into a new ribbon menu and adjusted the appearance and organization of interface widgets to offer a more logical workflow

- Access frequently used tools more directly, thereby reducing mouse movements and clicks

- Quickly find the functionalities that apply to selected objects by accessing a contextual tab or a simplified contextual menu

- Customize the ribbon menu by repositioning tools or integrating macro scripts

With PolyWorks|Inspector 2024, users are able to:

- Strengthen their skills by exploring various new tools at their fingertips

Easily Discover and Leverage Specialized Tools

Empower Datum Reference Frames with Surface Features

Surface datum features allow evaluating GD&T in the optimized alignment required by the assembly, with all of the constraints and mobility intended. With PolyWorks|Inspector 2024:

- Simulate the real physical constraint of a surface datum feature by controlling the considered degrees of freedom

- Calculate the best measured control results possible by optimizing surface feature alignment within its full profile tolerance allowances

Control the Fit of Probed Features

With this new release, PolyWorks|Inspector now offers direct control over the fitting parameters of probed features, which enables users to:

Predefine the fit type and constraints prior to probing to directly get the desired result

Modify the fit type and constraints after probing and automatically update the result

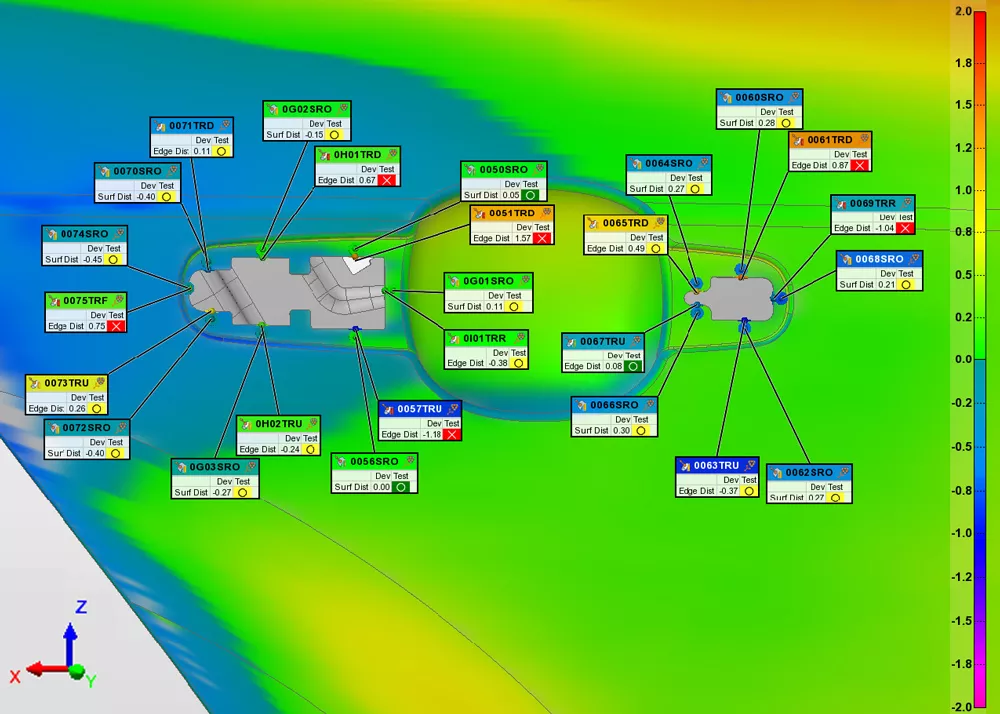

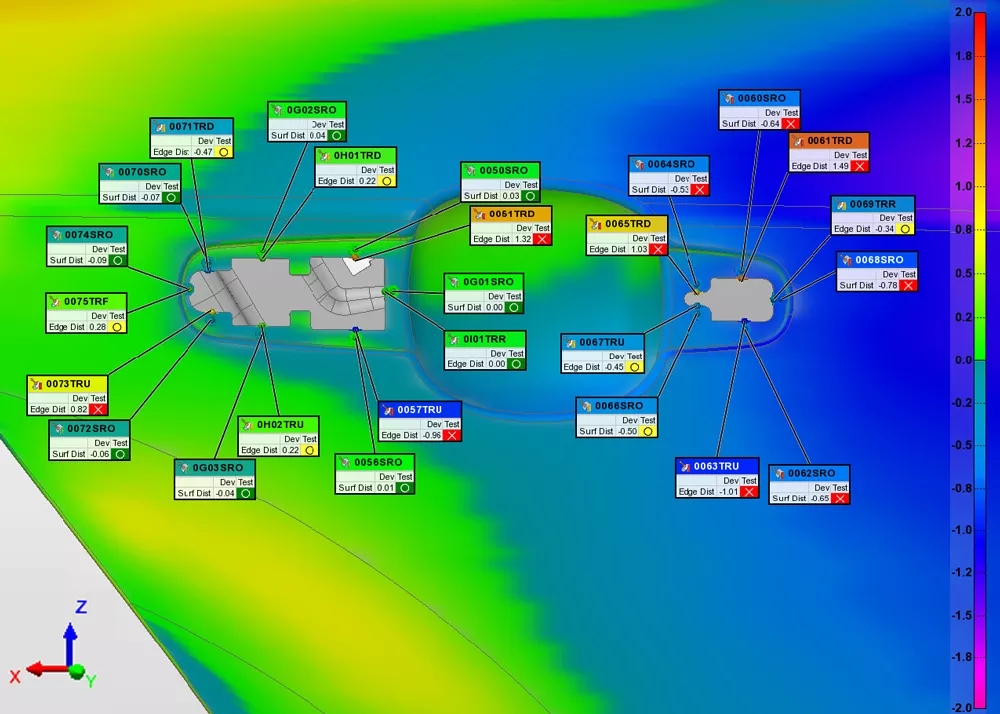

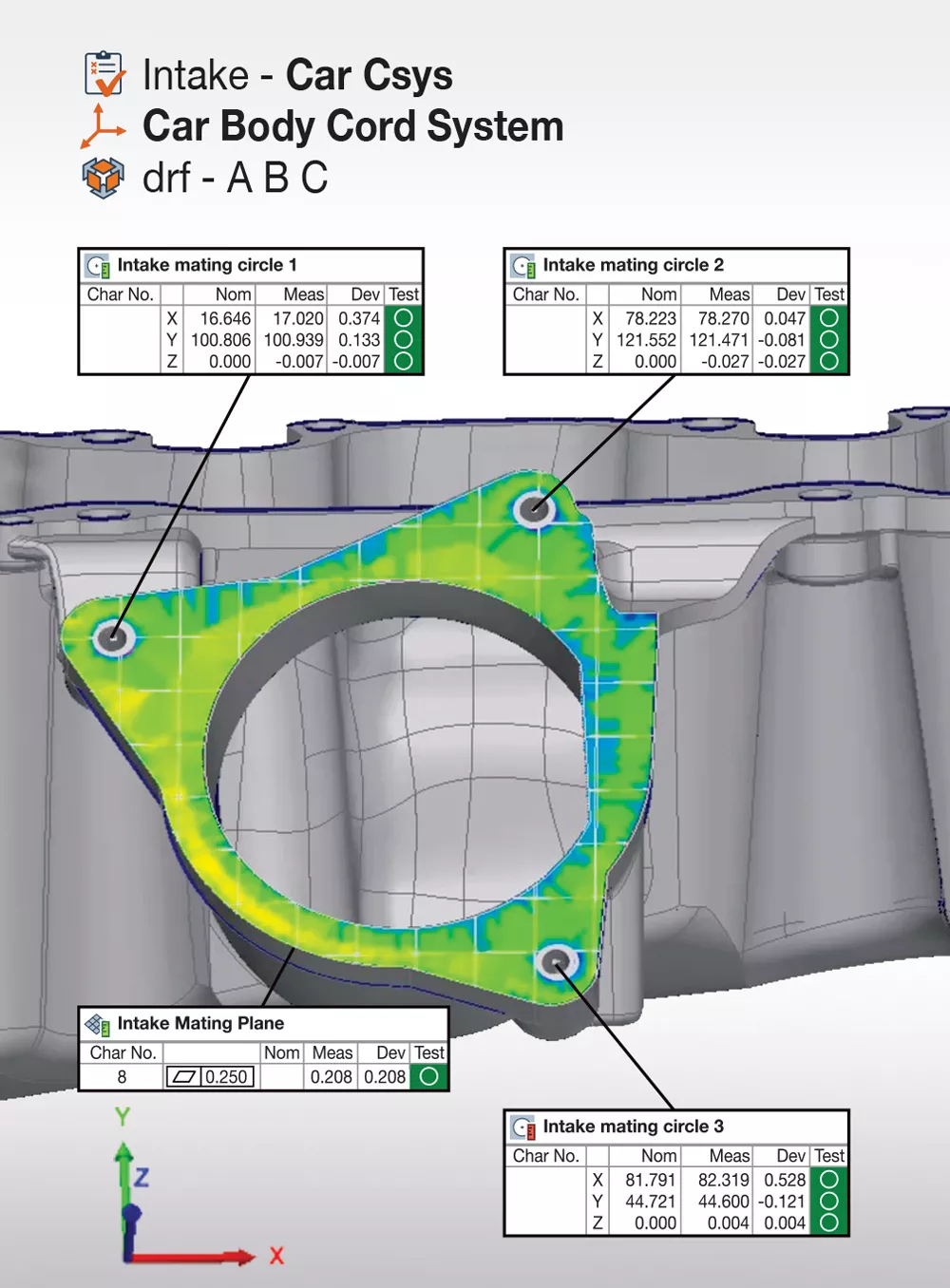

Improve Result Analysis and Reporting with Contextual Control Views

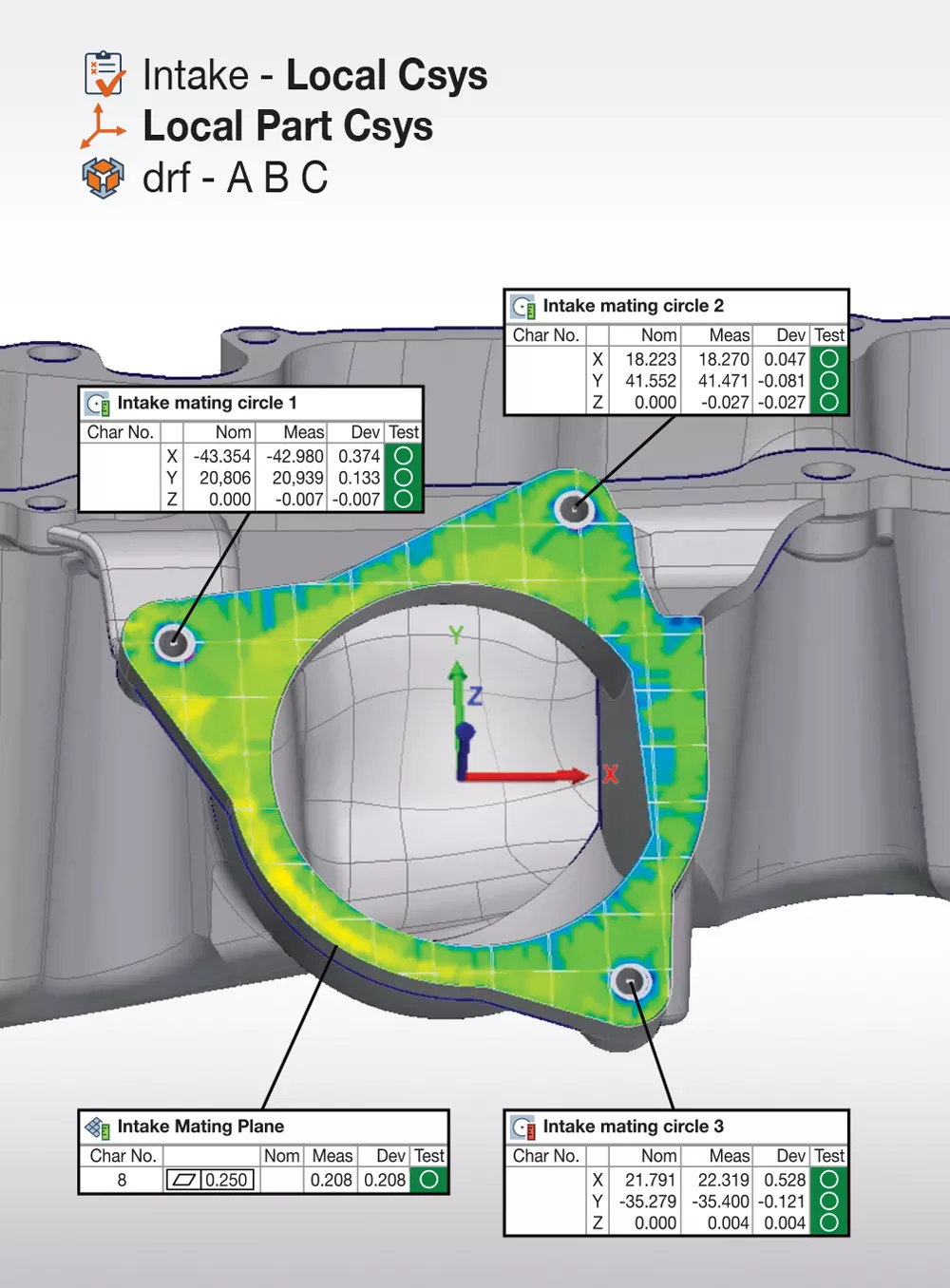

PolyWorks|Inspector already allows users to report 3D measurement results in multiple contexts using tables and snapshots. Version 2024 extends this capability to control views. Users can now select a set of dimensional controls, choose a data alignment as well as a coordinate system, and create a contextual control view to:

Analyze surface deviations in multiple alignments

With body alignment

With handle alignment

- Inspect dimensional controls in the tooling and assembly coordinate systems

With car body coordinate system

With intake part coordinate system

Perform CADless Inspection Workflows on CNC CMMs

CNC CMM operators can now create measurement sequences without any CAD data:

Prepare a CNC sequence easily by leveraging a new teach mode that records manually probed points and Go To points

Automate multipiece measurement by converting probed features from the first piece into measurement guides for subsequent pieces

Improve measurement repeatability by resampling measurement guides and generating uniformly distributed measurement points

Access MyPolyWorks online hub

Download software releases, master new skills,and connect with the user community.